How steel is proving a critical component in transport’s journey to net zero

Introducing the world’s first vehicle made from fossil-free steel. Image: Volvo.

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

Infrastructure

Listen to the article

- Radical decarbonization is possible if the transport, infrastructure and steel industries work together.

- Hydrogen has the potential to deliver far-reaching change, replacing fossil fuels in everything from steel production to transportation.

- Innovative, well-orchestrated collaboration – across companies and industry sectors – offers a solution to tackle the climate crisis.

In a constant search for new ways to reduce climate impact, big industries must find new solutions and think beyond the traditional, to identify new collaborative partnerships. In the transportation sector, vehicle production is one such route being explored, and it is leading to exciting new partnerships with the steel industry, currently a major contributor of greenhouse gas (GHG) emissions, but committed to changing its ways.

Steel accelerating the transition to net zero

In 2020, 1,878 million tonnes of crude steel were produced worldwide, 16% of which was destined for the transport sector. A staple of the world’s industrial economy and used in everything from energy and construction, to automotive and transportation, infrastructure, packaging and machinery, steel is everywhere. Lightweight but strong, it’s the perfect material for the automotive sector which demands durability, fuel and cost-efficiency, as well as a product that is easily repairable and re-manufacturable.

Whilst infinitely recyclable, demand for new, virgin steel is rising, as much of the steel already in existence is in use in products like bridges where it will remain for many years to come. On average 1.85 tonnes of CO2 are emitted for every tonne of steel produced and the industry is heavily reliant on fossil fuels, namely coal and natural gas, to reduce iron ore and produce the steel.

Steel – charting the roadmap to change

The steel industry accounts for around 8% of GHG emissions annually. Like the transportation sector, it is doing much to tackle its impact, driving more reuse, remanufacturing and recycling, all of which are key components of a circular economy. In the last 50 years, the steel industry has reduced its energy consumption per tonne of steel produced by 61%. But to continue to deliver improvements, the development of breakthrough technologies and the implementation of new processes will be critical.

Hydrogen – a revolution in steel production

Perhaps one of the most exciting innovations on the horizon for steel production is the use of hydrogen. By switching from fossil fuels to hydrogen for reducing iron ore, GHG emissions can be virtually eradicated and the only waste gas produced is water. This new approach offers one of the best opportunities to slash emissions from steelmaking.

Hydrogen has become a key area of focus for steelmakers like SSAB, and they are developing breakthrough hydrogen reduction technology. At Volvo Group, we are proud to be partnering with SSAB, who are providing us with the fossil-free steel we need to research, develop and commercialize the world's first vehicles made from green steel.

With around 70% of a truck’s weight coming from steel and cast iron – and the figure for Volvo construction machines even higher – their production will be another step in our journey to net zero. Coupled with the roadmap we have set to reduce our carbon footprint at the end-user phase through the electrification of our vehicles – either via battery-electric or hydrogen fuel cell technology – the potential to deliver significant change is compelling.

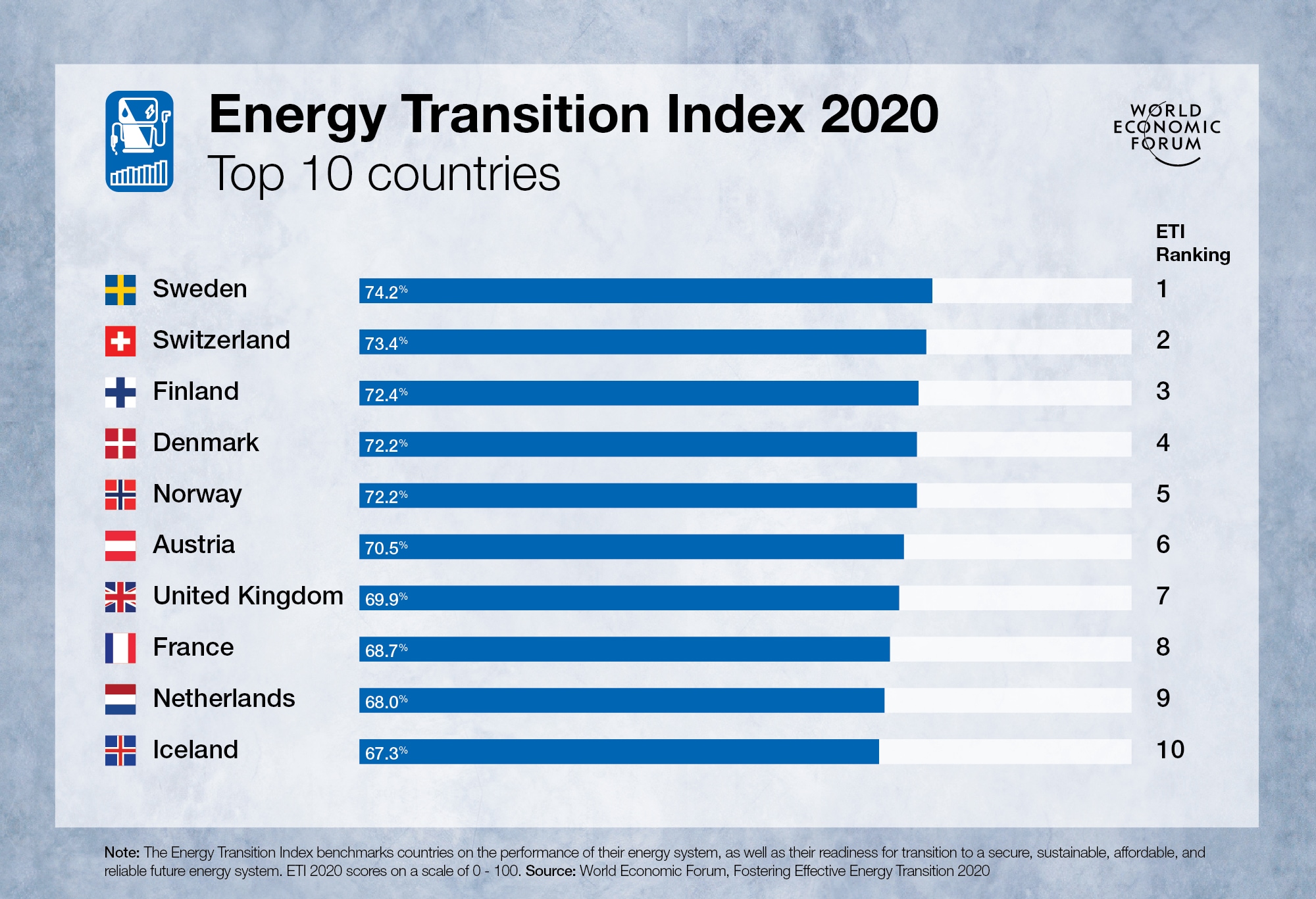

What's the World Economic Forum doing about the transition to clean energy?

For organizations committed to limiting their footprint and decarbonizing, it is imperative to look beyond one’s own operations to identify opportunities for improvement both up and down the supply chain. By demanding better, more sustainable products, we can be the impetus for achieving net zero.

Like SSAB, Ovako is also looking to use hydrogen in its steel production – using it to heat steel prior to rolling – and is constructing a new fossil-free hydrogen plant in Hofors, Sweden. A hydrogen filling station will be built alongside the plant, with the surplus hydrogen used to power Volvo’s next-generation trucks. Future installations at multiple locations would create a network of locally produced fossil-free hydrogen for the transportation sector. At Volvo Group, we see hydrogen playing an important role in our shift to electrification, with fuel cell power for the long haul and heavy-duty applications. Green hydrogen can also play a role as a fossil-free fuel for combustion engines.

Collaborate for systemic change

Just as the world’s nations come together at COP26 to address climate change, so industries and organizations must also work together. Few companies, if any, can achieve substantial decarbonization on their own. The development of a fossil-free value chain requires partnership, cooperation and shared learnings. Organizations should see themselves as part of the puzzle and not the complete solution to net zero. They need to identify inter-connections with other partners, be that suppliers, customers, academia, competitors, policy-makers and even other industries, and work to piece together the answer to today’s climate challenge.

Changemakers have the power to lead by example, through innovative, well-orchestrated collaborations that deliver much-needed change. They also set a benchmark that can be replicated by other organizations across the world. As European Commission President, Ursula von der Leyen, recently stated: “Our current fossil fuel economy has reached its limits. And we now have to move to a new model, one that is powered by innovation.”

And this is precisely what we are seeing emerge, as both the transport and steel industries look to work together to introduce ground-breaking new initiatives that will transform the way they operate and the products they provide to their customers.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Energy TransitionSee all

Nick Pickens and Julian Kettle

April 22, 2024

Katie Fedosenko and Luciana Gutmann

April 15, 2024

Johnny Wood

April 11, 2024

Alexandre Raffoul and Kai Keller

April 10, 2024

Roberto Bocca

April 10, 2024

Naoko Tochibayashi and Naoko Kutty

April 10, 2024